Screw Machining

We provide tight Davenport tolerances

We provide Tight Davenport Tolerances, needed for the highly automated assembly systems of today.

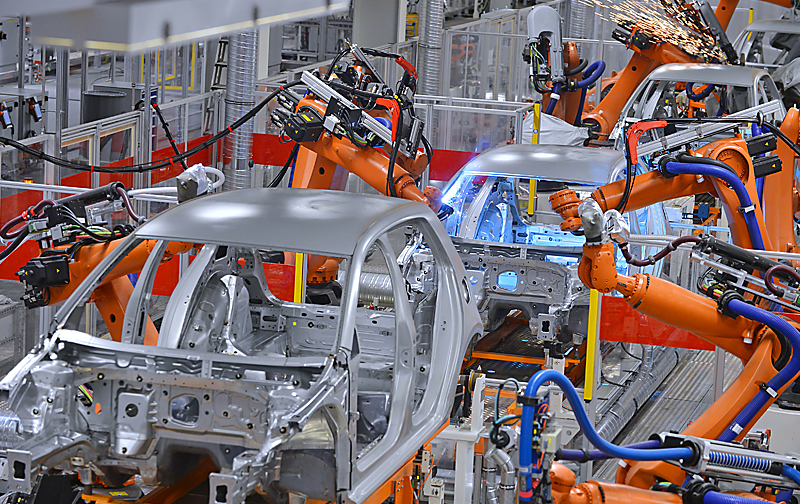

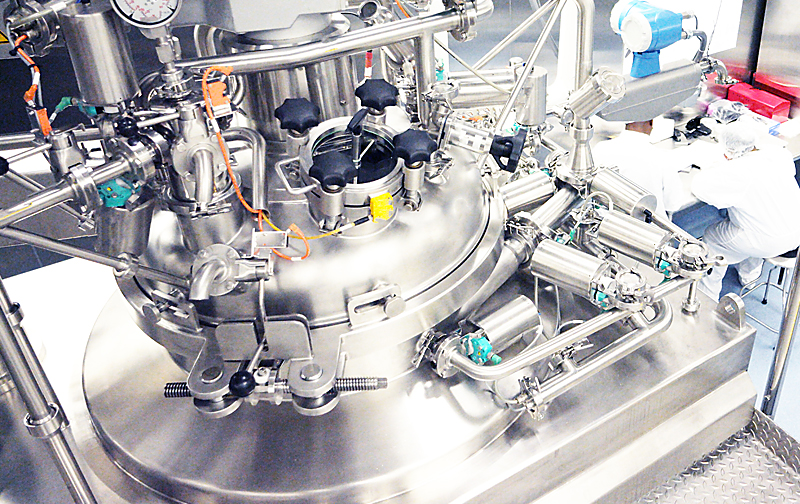

High Volume Production Screw Machining, include machine operations of Knurling, Milling, Threading, Trepanning, Slotting and Cross Drilling/Tapping. Kanban, JIT & PPAP are available to our customers in the Military, Commercial, Automotive, Medical, Electronics, Insert Molding & Fastener Industries.

Engineering & Design Assistance

JAY SONS offers engineering and design assistance to maximize cost effective production for any given part without altering its integrity or end function.

Special Operations

Our special operations include customer tooling maintained for repeat production and quick change cams for high production output.

As an added service to our customers, in conjunction with the companies engineering and design team, – JAY SONS will build and test all special tooling needed for any required job.

In the parts cleaning process JAY SONS uses non-ozone depleting substances as well as chip and oil recycling for sustainability.

Production Management

JAY SONS has a team approach for production management. Floor scheduling efficiencies for uninterrupted production flow and information tracking for:

- Cost Containment

- Quick Quotation

- Daily Production Efficiencies

- Bar Coding

- Raw Materials

- Finished Goods

- Scrap

- Shipping

Markets

Jay Sons Provides Tight Davenport Tolerances on all of our screw machine products for the following markets:

- Military/Ordnance

- Insert Molding

- Automotive

- Medical

- Electronics

- Appliance

- Fastener

- Connectors

- Hand Tools

- Marine

Contact Us Today About Your Next Project!

See Our latest projects, equipment, and all that is happening at Jay Sons, Inc.

Jay Sons Screw Machine Products, Inc.

197 Burritt Street

Milldale, CT 06467

860-621-0141